- |

- English

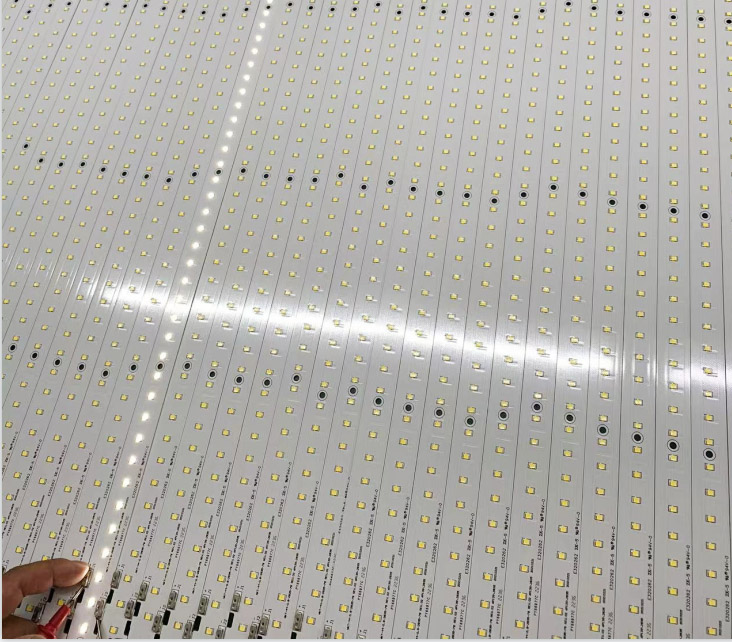

At NKT LED Lighting, every single led module/LED circuit board/LED PCB board is tested in house to assure high quality without bringing any concern to our customers. We follow the strict test procedures as belows:

Visual Inspection:

1. Take a close look at the solder points of led modules. If there are any cold solder joints on it, the led module is considered as defective.

2. Check if there are any components missing on the led PCBAs.

3. Check if there are any LEDs which are soldered on led modules reversly.

4. Set up a norminal current and norminal voltage for LED circuit board and light it on. If there are any leds which are not on, it is considered as defective.

5. For some complex LED boards, we have an experienced operation team equipped with advanced AOI and X-ray machines, which greatly reduces our led module repair rate.

Aging test

All LED PCBAs must remain powered for several hours before leaving the factory. Burn-in testing is common in mass production. From a descriptive point of view, it might be similar to reliability testing, but reliability testing focuses on the process, whereas burn-in is on the results. Like X-ray testing, burn-in testing is moving from one item to another. Details of such tests are always provided by the customer. We can test it the way you want.

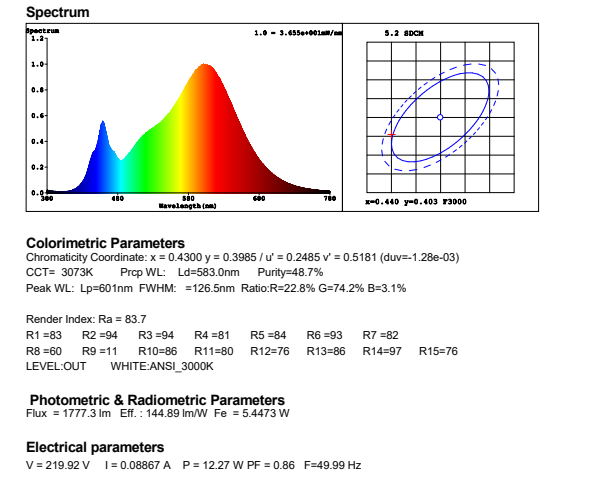

Spectrum Test

Spectrust test is a fundamental method to figure out some critical parameters of LED Modules like CRI, CCT, efficacy, lumen output for designing a LED Lighting fixutres or check if the led modules meet the criterion. Normally, a spectrum test will include the below information:

Chromaticity coordinates (x, y), chromaticity coordinates (u, v), correlated color temperature Tc, color purity, color tolerance, color rendering index: RI(R1~R5), color rendering index: RI(R6~R10) , Color rendering index: RI(R11~R15), Color quality table: RI(Q1~Q5), Color quality table: RI(Q6~...), Color quality table: RI(Q11~...), Pupil Luminous Efficiency, Sichen Vision Luminous Flux, Mesopic Luminous Flux (CIER.), Mesopic Luminous Flux (USP), Mesopic Luminous Flux (MOVE), Energy Efficiency Index (EEI), Energy Efficiency Level, Relative Spectral Power Distribution P(λ) (UV, Visible, near-infrared), optical radiation power, dominant wavelength λd, peak wavelength λp, half width Δλ, red ratio, green ratio, blue ratio, etc.

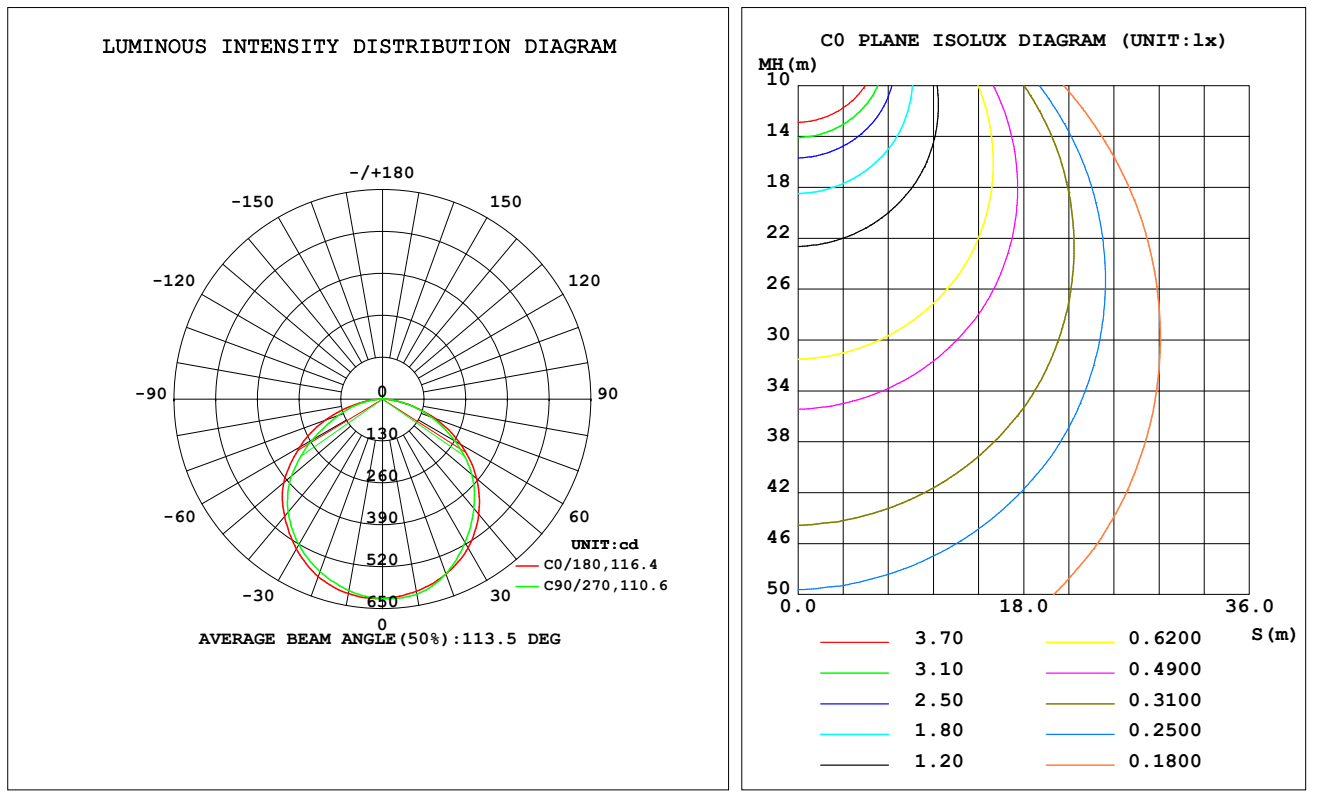

IES test

Running photometric tests and electrical performance tests is important for setting high LED lighting standards for testing and certification. Both tests help WCI get the correct light distribution, efficacy, beam angle, power factor, voltage and current. This is something every top LED manufacturer and supplier cares about, which is why we have established a UL certified laboratory equipped with all the necessary tools to provide our customers with these types of tests.