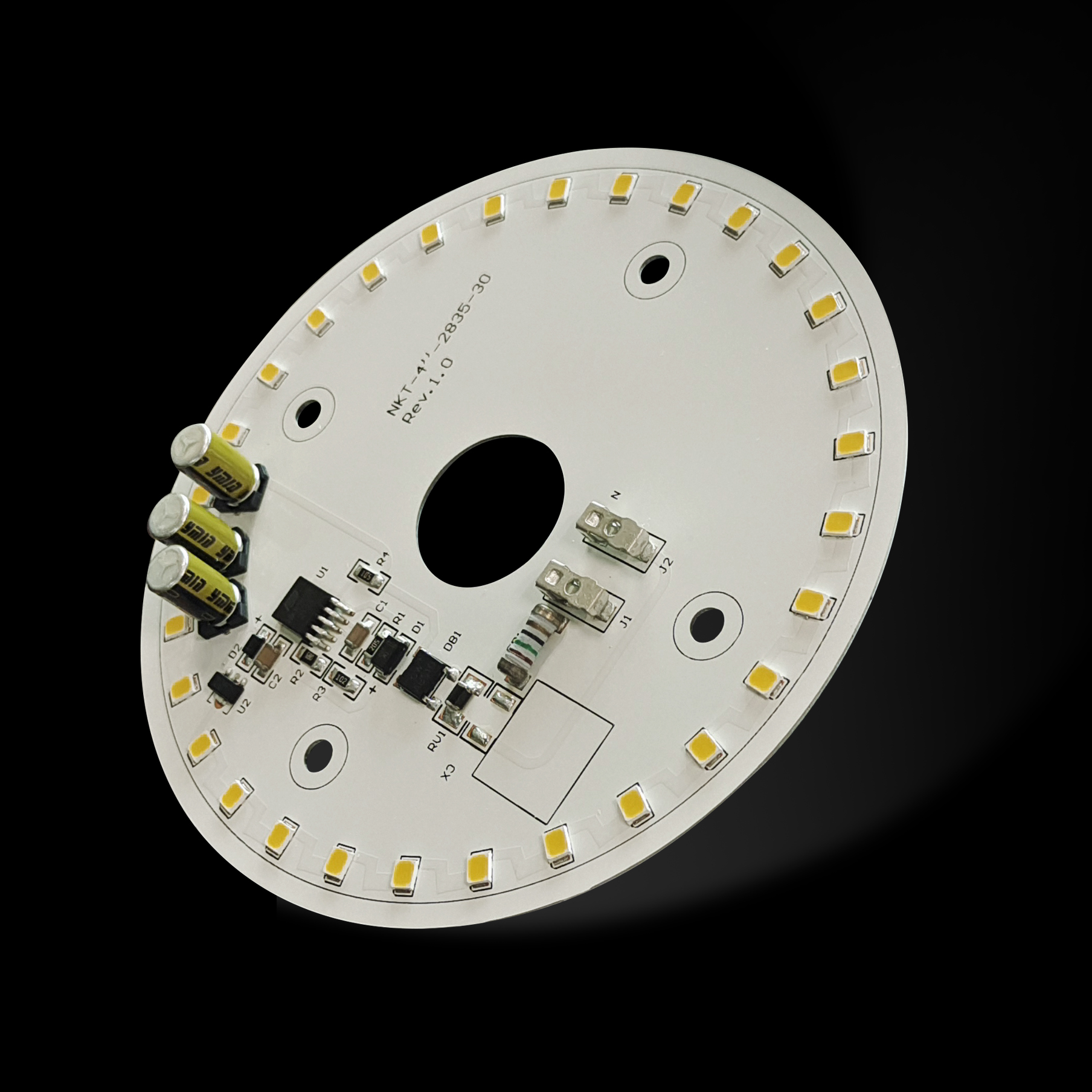

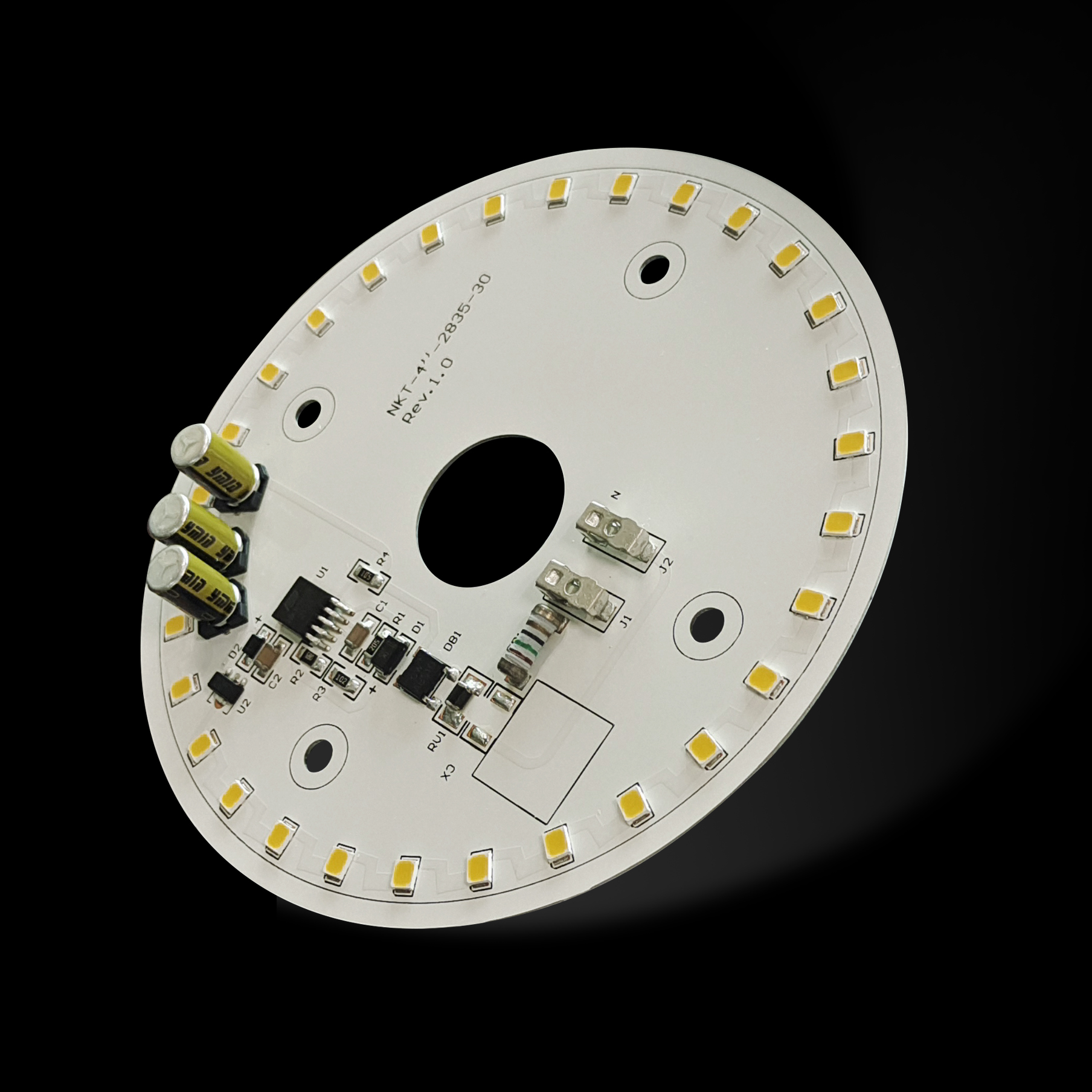

LED PCB boards are specific types of printed circuit board with LEDs on, designed for use in a wide array of lighting fixtures and applications. A number of light emitting diodes (LEDs) are mounted to a PCB forming a completed circuit, allowing full control of their behaviour through various types of chips or switches.

WHERE ARE THE LED MODULES USED?

The LED modules can be used in various LED lighting applications and different places.

Commercial & industrial lighting: Canopy light, Panel light, Down light, Track light, exhibition lighting, LED profile light, Linear High bay light, Low bay light, Parking garage luminaires, Tri-proof light, Troffer light.

Indoor lighting: Book light, Cabinet light, Ceiling light, Chandeliers & Pendant light, Desk light, Downlight, Floor lamp, Night light, Spotlight, Table light, Track light, Wall light.

Outdoor lighting: Flood light, Garden light, High mast light, Lawn light, Outdoor ceiling light, Outdoor wall light, Path light, Pillar light, RGB tube, Street light, Tunnel light, Under ground light, Wall washer.

Vehicle lighting: Automotive light, truck light, boat light, Marine light.

Professional lighting: Grow light, indicator light, Pool light, Aquarium light, Utraviolet light, Working light

All different types of applications have their own specific places to use. We list a few of them for Commercial and Industrial lighting:

Commercial Spaces: Business area such as offices, stores, universities, hospitals and government buildings.

Industrial Spaces: Warehouses, factories, manufacturing plants.

THE BENEFITS OF LED CIRCUIT BOARDS:

There are numtiple benefits to use LED circuit boards, some of them include:

Long service life:

Under the proper current and voltage, the service life of LED circuit boards can reach 100,000 hours. That is to say, the life of the lamp can reach more than 10 year, which is the only longevity star in the field of lighting.

Compact design:

Compared with traditional PCBs, LED PCBs are smaller and requiring less circuitry to run. As they are generally significantly thinner, they are much lighter and require less securing to hold them in place.

Low heat generation:

LED uses a more advanced cold light source. At the same time, the PCB board adopts aluminum material/CEM board, which have good heat dissipation function. Heat generated by the LEDs is sunk through the PCB core, so they do not build up heat as much as other lighting options.

Lower power consumption:

Incandescent lamps rely on filament heat to emit light. The principle of light emission is fundamentally different from that of LEDs, so the luminous efficiency is very low, and a large part of the electric energy is consumed as heat energy. This is nothing compared to LED lights. Data show that the energy consumption of LED lamps is only 1/10 of incandescent lamps and 1/4 of energy-saving lamps. The below table shows the comparison between Incandescent lamps, CFL and LED lights.

Available in a wide variety of sizes, colors, and intensities:

The led modules can be in different shapes like linear, Round, Square, or custom shapes, and in different sizes. They also allow different colored LEDs which can be placed in the circuit boards, like white at color temperature 2700K, 3000K, 3500K, 4000K, 5000K, 6500K, color leds like RGBW, RGB, blue, red, Amber, UV, etc.

Environmental Protection:

LED does not use high-hazard mercury like fluorescent lamps, that is why there is no public hazards such as mercury ions and phosphors leaking during the manufacturing process of the bulb or after damage. Moreover, the aluminum pcb and CEM pcb comply with the RoHs standard, so the LED Circuit boards NKT LED Lighting manufacture are environmental which help protect the earth.