- |

- English

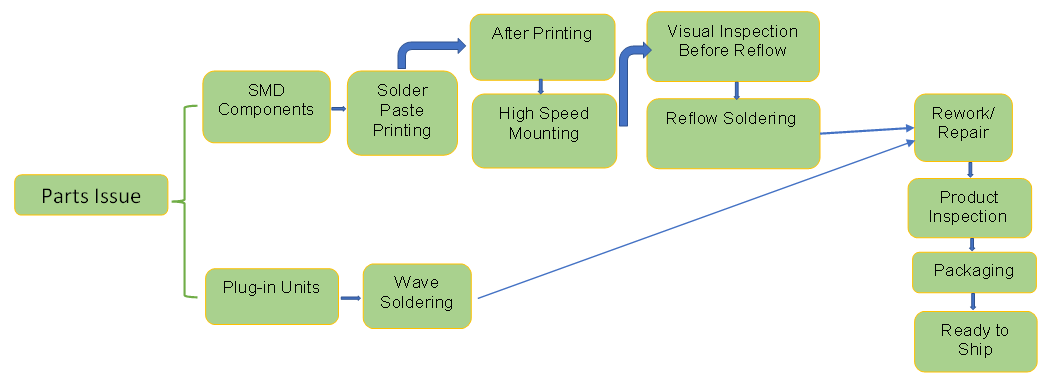

NKT LED Modules Production Process

NKT LED Lighting is a professional manufacturer of LED modules for more than 15years. With a group of experienced workers, each process is strictly implemented in accordance with quality standards. Here are the LED Modules/LED PCBA/LED PCB Production flow:

Parts Issue

The raw material warehouse issues all the parts according to order quantity:

DC LED Modules: Aluminum boards /CEM boards / FR4 boards, LEDs, Connectors.

AC LED Modules: IC, Resistors, Capacitors, Diodes and many other components.

Solder Paste Printing

1. Accurately fix the stencil on the printing machine according to the product model, and check whether the stencil corresponds to the product; Place the appropriate solder paste in the stencil. Be cautious that the solder paste must be stored in a low temperature environment.

2. Place the PCBs on the solder paste printing machine accurately, and print the solder paste on the PCBs with a special tool for brushing solder paste.

After Printing

Check whether the solder paste on the PCBs is symmetrical, more solder paste or less are not up to standard which are considered as unqualified products. Wipe off the solder paste with a towel or a cloth and print again. Qualified products flow to the next process.

High Speed Mounting(for SMD Components)

SMT placement machine is a machine that accurately places SMD (Surface Mount Device) surface mount devices on the corresponding pads on the PCB circuit board through a pick and place program. Surface mount devices include LED, capacitors, resistors, ICs and other devices that can be quickly and accurately placed on circuit boards by SMT placement machines.

Visual Inspection Before Reflow

Visually check whether all the components are correctly placed, whether there is any missing or wrong installation.

Reflow Solderining

Its function is to melt the solder paste, so that the surface mount components and the PCB board are firmly bonded together.

Rework/Repair

Repair/Rework the defective led pcb boards if there is any.

Plug-in Units

In the DOB/AC led modules, there are some plug-in units, like capacitors(in order to make flick-free LED boards, we would use some big capacity capacitors which only plug-in capacitors could achieve. To solder plug-in units needs wave soldering process.

Wave Soldering(For Plug-in Units)

The wave welding uses the pump to run the melted welded into a welded peak, and then the pins of the electronic component that need to be welded can be used to achieve electronic components and PCB board electrical connectivity.

Rework/Repair

Repair/Rework the defective led modules if there is any.

Product Inspection

All LED PCB boards need to pass 100% inspection to ensure that they are good products before packaging.

Packaging

Use foam to protect all the led strips/Round led boards, then stuff them into high grade export cartons. Customers will get the products safe and sound.

Ready to Ship

All finished products enter the warehouse and wait for transportation.