- |

- English

How to design and make a new flicker free ERP complied AC Module using the IC from Bright Power Semiconductor (BPS)?

A study by the European Union found that 80% of a product's environmental impact depends on the product's design stage. That is to say, if the methods and concepts of eco-design are introduced at the design stage and focus on the energy efficiency of energy-consuming products, the energy usage and adverse effects on the environment of the products during the entire life cycle can be greatly reduced.In order to design a high efficient energy-related product,we have to follow new ERP directive strictly.

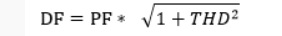

A lot of people probably don't how power factor relates to displacment factor. Let us make them simple and clear so you know how they are related.

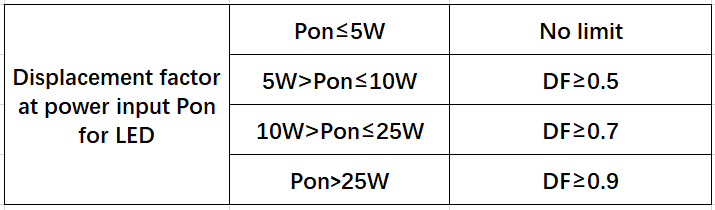

Displacement Factor requirement for AC module?

The new regulations stipulate that for products larger than 25W, DF requires ≥0.9, for a product smaller than 25W,DF≥0.7 is required. According to the relationship between DF and PF, it can be calculated that the PF value also needs to be ≥0.9 for a 25W product and ≥0.7 for a less than 25W product. In the actual test, the power factor of our 12W AC Module is 0.87, and we can calcuate the displacement factor>0.9 when we know the THD is 0.6, which is in line with the new regulation.

The relationship between power factor and Displacement factor and THD

The new regulations stipulate that Pst is less than or equal to 1 in the stroboscopic performance test. The test results of NKT's 12W AC Module shows that Pst is 0.371, which is in line with the new ErP standard Pst≤1.

In addition, SVM≤0.9 is required in the stroboscopic performance test (SVM≤0.4 after September 1, 2024). The test results of NKT's 12W AC module is 0.173, which is in line with the new ErP regulations.